- Provide professional technical support for speed reducer, reducer selection, reasonable offer.

- Hotline:+86 191-2910-8136

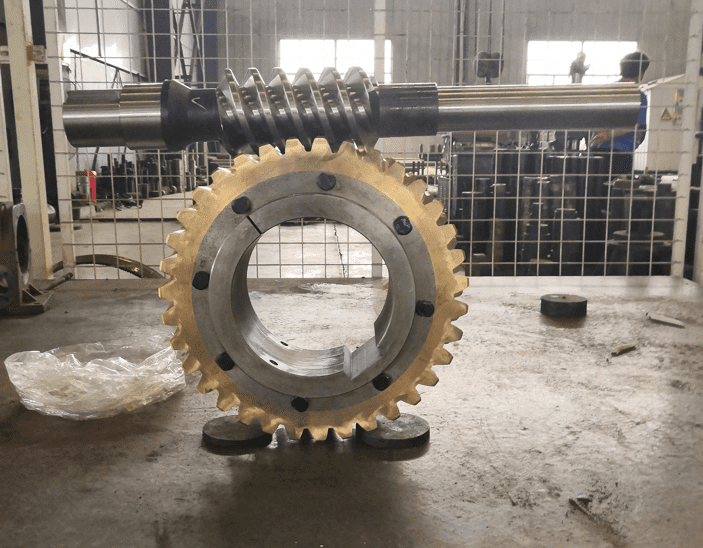

Friends who often have to use the reducer may find that the reducer may sometimes be found to have the phenomenon of gear pitting and peeling. But the actual normal reducer is not so easy to occur gear corrosion, peeling problems. What are the reasons for gear pitting and spalling? Causes of fatigue pitting in gear reducer Bellow:

Table of Contents

ToggleMaterial, hardness and defects – causes of fatigue pitting in gear reducer

The material of the gear does not meet the requirements. The main factor affecting the contact fatigue strength of the gear is the low hardness after heat treatment. This can not guarantee the contact fatigue strength of the gear should be. In addition, the tooth surface or internal defects, is also one of the reasons for the contact fatigue strength is not enough.

Gear precision is poor.

Gear processing and assembly accuracy does not meet the requirements, such as meshing accuracy, poor motion accuracy. There is also too much error in the center distance of the shell of the circular gear.

The lubricant does not meet the requirements.

The use of lubricating oil is not the right grade, the viscosity of the oil is low, the lubrication performance is poor.

Causes of fatigue pitting in gear reducerOil level is too high

The oil level is too high, the temperature of the oil rises, reducing the viscosity of the lubricant, destroying the lubricating properties and reducing the working thickness of the oil film.

in a word ,material, hardness and defects, Gear precision is poor,The lubricant level high,not meet the requirements causes of fatigue pitting in gear reducer.

Blake, Chu

Deeply committed to the speed reducer industry, the core products of the speed reducer for sale now are Gear Reducers,Worm Gear Reducers ,Cycloidal Reducers and custom Reducers.

Search

Recommended for You

Hot Tags

© 2025. All Rights Reserved.